by Arie Viewer

Among Corvette performance enthusiasts the Greenwood “Batmobile” Corvettes of the mid-1970s are an all-time favorite. These big block-powered monsters were the fastest and most brutally powerful IMSA GT cars of their day, recording trap speeds in excess of 220 mph at Daytona and many pole positions and fastest laps. The wins were fewer, especially in endurance races, because no one could manage to build a transmission that would stand up to the engine’s enormous torque for very long. In the shorter sprint races, however, if everything stayed together these cars were capable of not just winning but crushing the competition. And whether they won or broke there was no doubt that they were the baddest-looking Corvettes ever put on a race track.

Monogram’s 1/32 scale slot racing models of the Greenwood Corvettes capture the appearance of the cars marvelously with every aggressive line and contour right there to see. But performance-wise these cars have not enjoyed a reputation to match their looks. This is partly due to their front-motor layout, which makes them ill-suited to non-magnet racing and puts them at a disadvantage to rear-motor cars even with magnets. Still, there is hidden potential, and a couple of simple tricks will go a long way toward giving them the performance they should have.

In stock form the ultra-wide rear tires don’t deliver the grip they should. Switching to aftermarket tires, such as Maxxtrac M13 silicones, is worth several tenths of a second per lap, depending on the configuration of your track. However, the stock tires, with a little work, may be an even better choice. Their problem, as they come from the factory, is that their tread surface is seriously concave. This means that only the inner and outer edges of the tire are touching the track. Since traction on a dry surface is a direct function of the area of rubber in contact with the road surface (the “contact patch”, as it’s known) most of the potential traction of those fat tires is being lost.

The key to unlocking all that missing grip is to sand the tires so that the entire width of the tread surface touches the track, greatly enlarging the contact patch. This is easy to do. Start by using a rubber band to hold the trigger of one of the controllers on your track in the full-throttle position. This leaves both of your hands free. Wirth one hand, hold a piece of medium-grit sandpaper (150-grit works well) in place on the lane connected to your rubber-banded controller. With the other hand, hold the car in place on that lane so the rear tires are spinning on the sandpaper. Keep doing this until all the concave shape has been sanded off the tires. Check frequently to make sure you don’t overheat the motor.

Now here’s why, at least on these particular cars, sanding the stock tires may be better than using silicones. Most silicone ties these days are not sandable. You can try to sand them all day and nothing much comes off. Monogram’s stock tires, however, are very sandable. In fact, by the time you sand the tread surfaces square with the track you will find that you have taken a noticeable amount of the diameter off the tires. This has the effect of lowering the whole rear end of the car and with it the traction magnet. A small decrease in the height of the traction magnet can make a big difference in the amount of magnetic grip. In this case the change in grip is dramatic, yielding 2/10 of a second on our test track over the silicones.

Of course, we could go even farther with the sanding and get still more grip. Because the Monogram Greenwood is an in-line car with a fairly small diameter crown gear we could take the tires down considerably farther than, for instance, on the Scalextric TransAm cars with their spur gears that are not all that much smaller in diameter than their tires. We didn’t do that because our goal here was to make the Greenwood Corvette competitive with our silicone-shod Scalextric TA’s and no more. Your objectives and, therefore, the amount of rubber you take off the tires may vary.

Because front-motor cars, with their front-heavy weight distribution, are more magnet-dependent than rear-motor cars the Corvette’s magnet installation is worth a look, too. The magnet is strong, registering 342 grams of downforce on our Magnet Marshal. However, it’s only ¾” long and doesn’t provide downforce over as much of the car’s width as we would like. The more of the car’s width covered by the magnet the more the rear end can slide out on the corners before the magnet is no longer over the track’s steel contact strips and the car abruptly loses most of its grip, usually with catastrophic results. A longer (or wider, if you prefer) bar magnet lets the rear end slide out farther and makes a more drivable and therefore faster car.

The standard bar magnet that comes in most Scalextric cars is a full inch long, and there is a flat area on the bottom of the Corvette’s chassis just forward of the rear axle that is perfect for gluing one to. The stock magnet installation is easy to remove. Just use the end of your screwdriver to push on the forward end of the magnet housing so it snaps out of its position, allowing the housing to drop away from the bottom of the chassis.

There’s a Monogram logo molded into the chassis in part of the area where you will glue the Scalextric magnet, so use an emery board to remove it and make the area perfectly flat. Use the emery board again to roughen one side of the magnet so the glue will grip it better. Then spread a thin coat of CA glue on the roughened side of the magnet and place it as shown below. As soon as the glue sets you’re ready to track test the car.

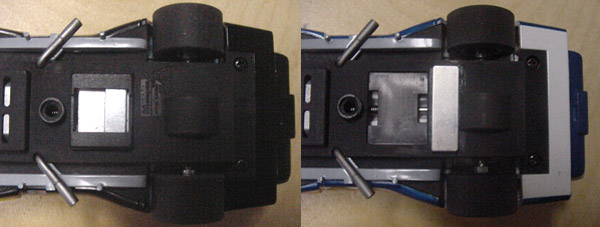

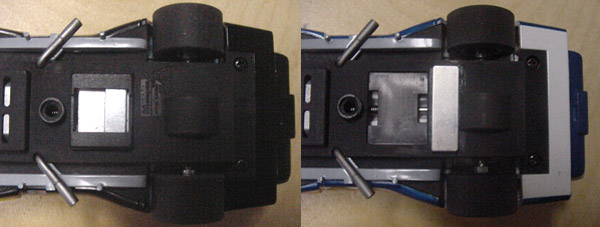

The Scalextric magnet actually reads a few grams less than the stock magnet installation on the Magnet Marshal (339 to 342) but the extra magnet width allows the car to be driven harder through the turns. It lowered lap times by another 2/10 of a second while giving the car a better feel and making it more forgiving to drive. Shown below are the stock magnet installation with silicone tires (left) and the Scalextric magnet installation with sanded stock tires.

You can use various combinations of tire type and diameter and magnet height, location, strength, and shape to adjust the performance of many cars from different manufacturers and equalize them for competitive racing. If you need both aftermarket tires and a different magnet for a particular car it will cost you about seven to eight dollars, but for many cars only one of the two and perhaps neither will be needed. The Greenwood Corvette, with sanded stock tires and a Scalextric magnet, fits comfortably into a racing class for Scalextric TransAm cars and L88 Corvettes that run box-stock except for silicone tires, adding variety to the competition and opening it up to increased participation at a cost of about $2.50 per car. Even better, it turns a car that some have thought of mostly as a shelf queen into a drivable and competitive race car.

As bargains go, that’s hard to beat.

Article Update

A few weeks ago we published an article about simple, inexpensive performance upgrades to the Monogram Greenwood Corvette. The changes described in the article comnpletely transform the way the car drives and turn it from a shelf queen into a serious competitor on plastic tracks. Since then we have added to our test car another simple, inexpensive modification that takes an additional 2/10 second off its lap times on our Scalextric Sport test track.

All you need is a Slot It SICH07 guide and a package of SISP05 braid, along with a Phillips screwdriver and a hobby knife. The guide has a long, deep, thick blade that takes maximum advantage of the width and depth of the slots on your track. It’s actually made for wood tracks so the blade will have to be trimmed a bit for most plastic tracks. The nice thing about it is that you can trim it right to the maximum depth your track will accept. Your hobby knife works just fine for the trimming. The guide fits the chassis with no modifications required to either. The screw and washer that come with the guide ensure that the guide will stay securely located no matter what happens. The guide post is a perfect, freely turning fit for the socket, much better than the stock guide, which wobbles badly in its mounting. The connectors on the car’s lead wires are a snug fit, and the Slot It copper braid gives much better electrical contact with the track.

This mod will take you all of 5 minutes to do and will make your Greenwood Corvette an even fiercer competitor on the track. This same upgrade will work just as easily on many other cars with the same kind of results.

unlike the carrea cars which have a switch underneath chassis for car to run different direction on track…can you make the monogram chevrolet greenwood vette (NO switch)go opposite direction on track in any way. If so, please explain how..

Many thanks !